Description

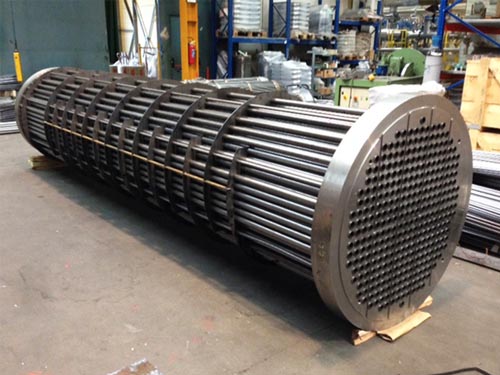

Air Cooled Heat Exchangers are designed and constructed so that the hot process fluid to be cooled flows through a tube while the cooling air flows across […]

Air Cooled Heat Exchangers are designed and constructed so that the hot process fluid to be cooled flows through a tube while the cooling air flows across the outer surface to remove heat. The cooling air is propelled by fans in either a forced draft or induced draft configuration. These Heat Exchangers can be Cover Plate / Plug Box and pipe bend models. Tube materials can be carbon or low alloy steel, stainless steel, copper, copper alloys and nickel alloys. Fin materials which are attached to the outer surface of tubes in order to create large surface area, can be of Carbon steel, Aluminum, Marine grade Aluminum and Copper Materials. Fin Type can be Plain or Crimped with ‘L’ or ‘G’ Type, Extruded or Embedded. Special imported heavy duty fans & motors are fitted for outdoor applications. Designing is done considering fouling, condensation, velocity of the air flow and enhanced tube surface area being provided by fins. The mechanical design of the exchanger takes utmost care of the process conditions including pressure, temperature, corrosivity and ease of maintenance.